Quick Turn Rigid

Description

Basic Info.

| Model NO. | FLCA-Q009 |

| Processing Technology | Electrolytic Foil |

| Base Material | Polyimide |

| Insulation Materials | Epoxy Resin |

| Surface Finishing | Enig |

| Silkscreen | White |

| Shipping Type | DHL.TNT, EMS, FedEx, UPS etc |

| PCB Design | Custom Design Product |

| Lead Time | 4-5 Working Days |

| Board Thickness | 0.1 mm |

| Solser Mask | Yellow |

| Copper Thickness | 1 Oz |

| Board Layer | 2 |

| Board Material | Polyimide |

| Transport Package | Vacuum +Carton Packing |

| Specification | RoHS, ISO9001, UL, SGS |

| Trademark | FL |

| Origin | Shenzhen, China |

| HS Code | 8534009000 |

| Production Capacity | 20000square Meter/Mon |

Product Description

Quick Turn Rigid-Flex Board Manufacturing

Dear buyer,

Thank you for scanning our website about FPC.As is known,PCB is customized product ,so the unit price is not real,details please contact me and a quotation will be offered.Please send us PCB files in gerber files, ".pcbdoc", ".lay", ".lay6" or ".brd" .

Product Description

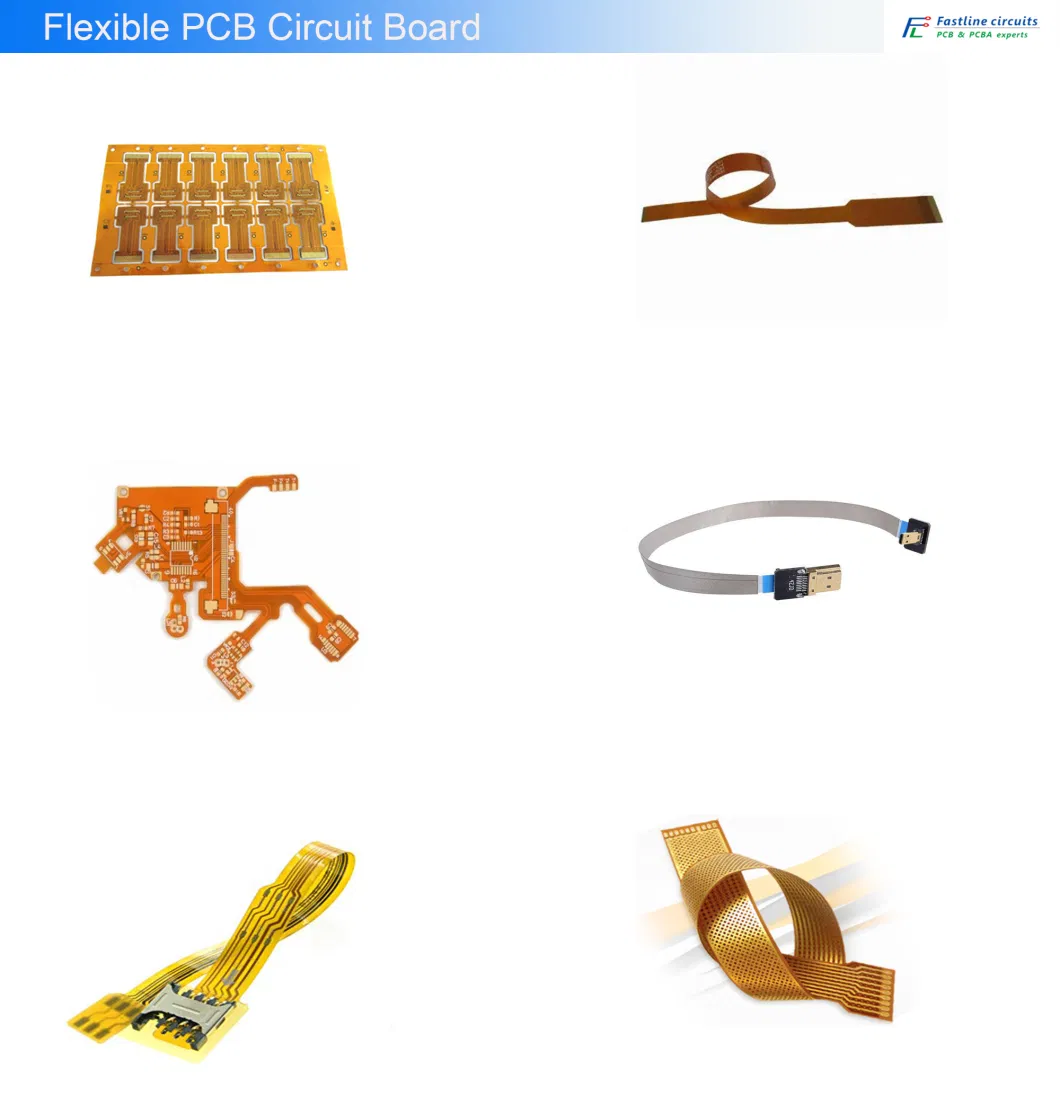

Standard Flex Materials:

Polyimide (Kapton) : 0.5 mil to 5 mils (.012mm - .127mm) Adhesiveless Copper Clad Base Material : 1 mil to 5 mils Flame Retardant Laminate, Base Material, and Coverlay High Performance Epoxy Laminate and Prepreg High Performance Polyimide Laminate and Prepreg UL and RoHS Compliant Material on request High Tg FR4 (170+ Tg), Polyimide (260+ Tg)

Base Copper: 1/3 oz. - .00047 in. (.012mm)--rarely used 1/2 oz. - .0007 in. (.018mm) 1 oz. - .0014 in. (.036mm) 2 oz. - .0028 in. (.071mm)

Solder Mask: Polyimide Coverlay: 0.5 mil to 5 mils Kapton (.012mm - .127mm) with 0.5 to 2 mil Adhesive (.012mm - .051mm) LPI and LDI Flexible Soldermasks

Flex PCB Capability

Fastline Circuits Co., Limited | |

FPC Technology and Capabilities | |

Material | FR4,Polyimide / Polyester |

Counts | Flex: 1~8L; Rigid-Flex: 2~8L |

Board Thickness | Min.0.05mm ; Max. 0.3mm |

Copper Thickness | 1/3 oz --- 2 oz |

CNC Drill Size (Max) | 6.5mm |

CNC Drill Size (Min) | Flex: 0.15mm |

Holes Location Tolerance | ±0.05mm |

Coverlay Drill Size (Min) | 0.6mm |

Hole to Coverlay Opening Windows (Min) | 0.15mm |

Min Line Width / Spacing | 0.1/0.1mm |

Copper Thickness on Hole Wall | Flex:12-22μm |

Min Pad Size | φ0.2mm |

Etch Tolerance | Finished line width tolerance ±20% |

Pattern Registration Tolerance | ±0.1mm (Working Panel Size: 250*300mm) |

Coverlay Registration Tolerance | ±0.15mm |

Solder Mask Registration Tolerance | ±0.2mm |

Solder Mask to PAD | Non photosensitive: 0.2mm |

Photosensitive: 0.1mm | |

Min. Solder Mask Dam | 0.1mm |

Misregistration Tolerance | ±0.30mm |

for Stiffener, Adhesive, Glue paper | |

Surface Finish | Plating Ni / Au ; Chemical Ni / Au ; OSP |

Would like to know more about the product? Send us inquiry, click "Send" now!

Please feel free to send us gerber file for lastest price and discount!

Contact Person:Grace Zhou Web:fastlinepcb.en.made-in-china.com

Prev: 94V0 RoHS Flexible PCB Board 2

Next: Rigid

Our Contact